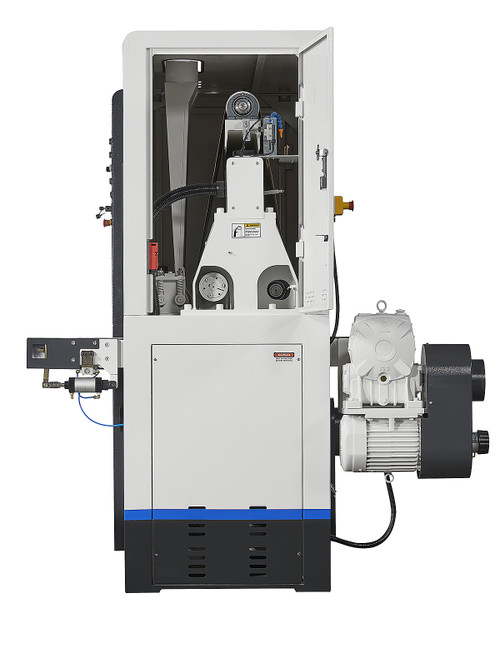

Ironwood’s engineering team designed the S134MRK triple head wide belt sander to be a robust blend of innovation, dependability, and quality. It is the most technologically advanced model of the Ironwood wide belt sander series; designed for a serious woodworker who demands absolute precision in sanding. The S134MRK includes a helical cutter head in the first position, a rubber contact roller immediately following, and combination head in position three. All sanding heads feature poly-v-belt drives and height adjustable contact rollers with position indicators for grit compensation, enabling quick set-up times and maximum stability, precision, and sanding quality.

Simple and Intuitive Controls

- Controller quickly adjusts machine thickness (+/- 0.1mm or 0.004”)

- Controller storage capacity of 99 programs for easy and fast adjustment

- Displays in mm or decimal inches (3 decimal places for inches)

- Simple push button controls for turning on and off each head

- Control switch with key for service or operation mode

- Amp meters for each sanding head

- Hour meter display

- Emergency stop

Sanding Heads

- 42” Triple head wide belt sander

- Head # 1 is a helical planer head

- 150 mm diameter helical cutter head

- 30 x 12 x 1.5mm carbide inserts

- Height adjustable planer head with scale

- Thirty (30) horsepower motor

- Head #2 is a rubber contact roller

- 250 mm diameter 85 shore profiled rubber contact roller

- Height adjustable contact roller with dial indicator for grit compensation

- Twenty (20) horse power motor

- Poly-v belt drive

- Cutting speed of 20 mps (65 fps)

- Cutting direction with feed

- Head #3 is a combination head

- 140 mm diameter 65 shore profiled rubber contact roller

- Height adjustable contact roller with dial indicator for grit compensation

- Height adjustable sanding pad

- Fifteen (15) horse power motor

- Poly-v belt drive

- Air jet belt cleaning

- Cutting speed of 12 mps (40 fps)

- Cutting direction against feed

Key Features

- Poly-v belt drive for all sanding heads for smooth and vibration free sanding head operation

- Height adjustable contact rollers on all sanding heads with dial indicators for quick and easy setup and grit compensation

- Rubberized hold down rollers before and after each sanding head with double hold down rollers at infeed and outfeed for consistent hold down

- Variable speed conveyor 3.6-14 mpm (12 – 46 fpm)

- Conveyor table mounted on four heavy duty jack screws for smooth, stable, and accurate height adjustment

- Adjustment hand wheel for quick and easy fine height adjustments

- Automatic conveyor belt tracking for worry-free conveyor belt operation

- Diamond style conveyor belt rides along robust steel conveyor table

- Electronic abrasive belt tracking

- Abrasive belt trimming for quickly and easily centering sanding belts for optimal sanding belt tracking

- Abrasive belt tensioning adjustment located on front of machine with safety switches for belt breakage

- Large diameter tensioning rollers (164 mm on R head, 120 mm on K head)

- Abrasive belt loading assist for all heads

- Abrasive belt run-off protection

- Pneumatic disc motor braking system

- Workpiece over thickness protection system

- Safety switches on all access doors and emergency stops at infeed and outfeed locations

- Infeed roller table with 2 infeed rollers

- Robust steel machine frame

- UL/CSA machine electrical components

- (Optional) Panel cleaning brushes and vacuum hold down available upon request, and may require additional lead time for special order machines

Specifications

- Working width max.: 1070 mm (42”)

- Conveyor belt width: 1100 mm (43”)

- Abrasive belt width: 1100 mm (43”)

- Abrasive belt length: 1900 mm (75”)

- Work piece thickness min.: 9 mm (3/8”)

- Work piece thickness max.: 150 mm (5.9”)

- Work piece length min.: 450 mm (17.5”)*

- MAX STOCK REMOVAL ON PLANER HEAD: 4 MM (0.15")

- Variable conveyor speed: 3.6 – 14 MPM (12 - 46 FPM)

- Feed motor: 5 HP

- Table rise/fall motor: ½ HP

- Head #1: Helical cutter head: 20 HP 65 fps belt speed

- NUMBER OF INSERT KNIVES ON PLANER HEAD: 159

- KNIFE INSERT SIZE: 30 X 12 X 1.5 MM

- Head #1: Rotation direction: Against feed

- Head #2: 250mm Ø 85 shore rubber contact roller: 20 HP 65 fps belt speed

- Head #2: Rotation direction: Against feed

- Head #3: Combination head – 140mm Ø 65 shore rubber contact roller with felt pad: 20 HP 40 fps belt speed

- Head #3: Rotation Direction: Against feed

- Electrical connection*: 460V | 3-Phase | 60 Hz.

- Dust collection requirements: 3,070 CFM

- Dust extraction ports: 6 ports | 123 mm (5”)

- Compressed air requirements: 90 PSI

- Air consumption per cycle: 4 CFM**

- Air jet belt cleaning air consumption: 24 CFM***

- Machine net weight: 3,765 kg (8,300 lbs.)

- Machine gross weight: 4,060 kg (8,951 lbs.)

- Shipping dimensions (LxWxH): 105” x 86” x 89”